제품소개 Products

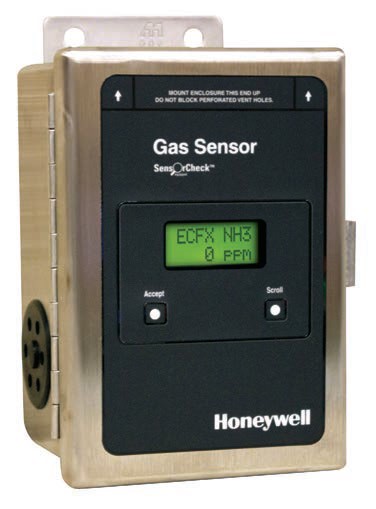

암모니아 가스 감지기 모델명: EC‑FX‑NH3 Sensor and Transmitter

► Features an all-new ammonia sensor with a proprietary electrolyte

that stands up to harsh environments

► You’re monitoring ammonia in blast freezers, cold storage or engine

rooms, you can feel confident in the effectiveness of your gas

detection system

► Helping you ensure life safety, prevent food spoilage and manage costs

※ For industry and laboratory application only

제품 카달로그

제품문의

Three harsh environments. One tough sensor

Cold Storage

From banana rooms to ice cream storage to food processing facilities, your cold storage areas are subject to extremely low temperatures — plus changes in humidity during cleaning and changes in pressure due to opening and closing doors. These fluctuations can cause some ammonia sensors to go into fault or false alarm. But since workers are often present in these areas, it’s critical for ammonia sensors to stand up to tough conditions and accurately report gas at low levels.

Refrigerated Processing Areas

Some of the harshest environments in the food industry are spiral freezers and blast freezers, where rapid freezing often means drastic changes in temperature. This temperature shock — along with humidity shock from hot-water washdowns — can further challenge the resilience of your ammonia sensors.

Engine Rooms

Finally, the most likely places for a catastrophic ammonia leak are often your engine rooms, since they typically hold ammonia for use throughout your plant. But in the hot conditions of most engine rooms, the liquid electrolytes in standard ammonia sensor cells can dry out quickly, sometimes reducing the sensor’s life span and causing false alarms.

General Specification |

|

Use |

Electrochemical (diffusion) type sensor that works in conjunction with any Honeywell Analytics readout or alarm unit. Readouts

|

Common Operation |

|

Operation |

In units without the optional LCD module, a group of LEDs are installed to the PCB. In units with the optional LCD, two external push buttons, “Accept” and “Scroll” are used to navigate test functions and operating modes. |

LCD display (optional) |

2 line by 8 alpha numeric characters and continuous backlight |

Output |

Isolated 4/20 mA, 700 ohms max. at 24 VDC. Signal output reduces to 0.5 mA to indicate a fault condition. RS-485, Modbus

|

Accuracy |

±5% full scale* |

Environmental IP rating |

Indoor use, IP 44 in accordance with EN60529:1992 |

Operational |

|

Humidity |

5-100% RH (condensing) |

Temperature |

-50°F to +120°F (-45°C to +49°C), ATMOS™ equipped enviro-adaptive technology required for refrigerated areas or outdoors |

Sensor Pressure Limit |

0-10 PSIG |

Storage |

-40°F to +176°F (-40°C to +80°C), 20 to 80%RH (non condensing) |

Common Module |

|

Communication |

4/20 mA output: #18/3 shielded cable (Belden 8770 or equal), cable runs < 1,500 ft. RS-485: for communication cable, use 24 AWG twisted pair, shielded (Belden #9841 or equal), cable runs up to 2,000 ft. For power cable use 14 AWG (Belden #5100UE or equal), cable runs up to 1,000 feet. |

Power Source |

24 VDC, 0.5 amp max. |

Repeatability |

<10% of full scale |

Sensor Specifications |

|

Sensor Pressure Limit |

Atmospheric ±10% |

Response Time (T90) |

<30s for EC-FX-NH3-LR ranges 0-100 ppm, 0-200 ppm, 0-250 ppm and

|

Ranges |

0-100 ppm, 0-200 ppm, 0-250 ppm , 0-500 ppm, 0-1000 ppm |

Sensor Warranty |

Three years from date of shipment |

Sensor Viability Test |

SensorCheck™, an internal microprocessor determines the sensor’s electrical viability every 24 hours. If the viability test fails, a 0.5 mA signal will indicate a fault. An internal light will show if a sensor is dried up or disconnected. |

Enclosure |

NEMA 1, gasketed, #16 gauge steel (standard). Stainless steel, including modified enclosures for low temperatures, ventilation ducts, etc. are available. |

Weight |

3 lbs (1.36 kg) |