Features

-

Microsecond Response to Metal Wall

-

Surface Temperature Changes

-

Allows Very Short Duration Testing

-

Available Probe Diameters from .015 Inch

-

Precise Location of Thermocouple

-

Rugged Renewable Junctions

-

Withstand High Pressure and Heat Flux

Applications

-

Wind Tunnel Model Surface Temperature

-

And Heat Flux Measurement

-

Inside Surface Temperatures of engine cylinders, air compressors, gun barrels, bearings

-

Die Casting Dies

-

Blast Effects on Structures

-

Laser Target Surface Temperatures

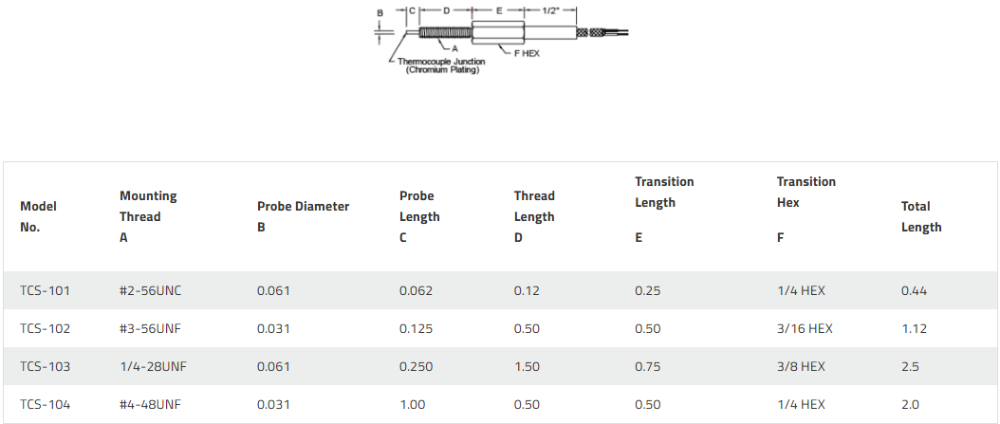

Standard Configurations

Over the years, four standard configurations have been found to cover a wide variety of applications. The dimensions are shown below: