제품소개 Products

질량 KOLAS Pipette Check to Standard DIN 모델명: Pipette Check to Standard DIN

According to Standard DIN EN ISO 8655-2 volumetric measuring instruments such as piston pipettes must be checked at regular intervals but at least once per year. Shorter time intervals may be specified by the users depending upon the frequency of use, number of users, aggressive nature of the pipetted liquids and the acceptable maximum permissible errors established by the user. In consequence for all laboratories that have to work in compliance to standard DIN EN ISO 8655 the regular check is mandatory

※ For industry and laboratory application only

제품 카달로그

제품문의

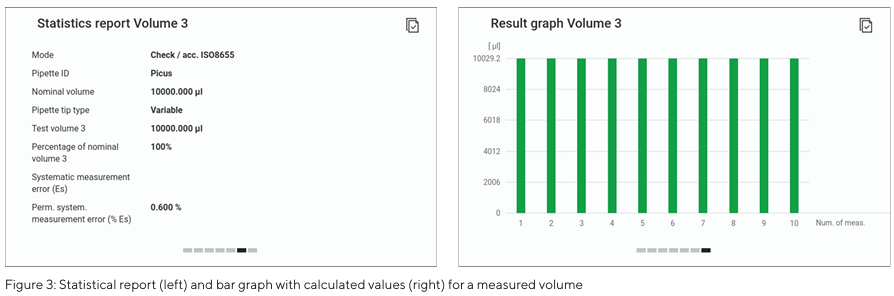

Piston pipettes can be checked by photometric, titrimetric or gravimetric methods. DIN EN ISO 8655 part 6 describes the prerequisites, procedure and evaluation of the gravimetrical test method. Each test can consist up to 30 pipetting steps and calculations like the mass loss due to evaporation, conversion of mass to volume, systematic error and random error. The calculated systematic and random error are used for conformity evaluation according to permissible error rates listed in DIN EN ISO 8655 part 2. Due to the number of pipetting steps and calculations the test procedure and evaluation is error prone without user guidance and auto matic record of measured values and results calculation.

Cubis® II MCA balances with evaporation limiting moisture trap (Fig. 1) and QApp pipette check offer a convenient solu tion to check piston pipettes according to DIN EN ISO 8655. The test shall be carried out in a draught-free room with a stable environment and temperature, air pressure and relative humidity during the measurement must be recorded using a thermometer, barometer and hygrometer. In the QApp software devices for measuring the ambient condi tions are recorded or alternatively by a climate module connected to the balance the temperature, air pressure and relative humidity are automatically measured and recorded

The temperature and air pressure are used to determine the z-factor according to table A1 in annex A of DIN EN ISO 8655 part 6. The z-factor is used to convert weight values into volume values by multiplying measured weight values with the z-factor. According to the standard DIN EN ISO 8655 also the time must be recorded. The time is measured and recorded the internal real-time clock that can be synchronized with an NTP time server at regular intervals.

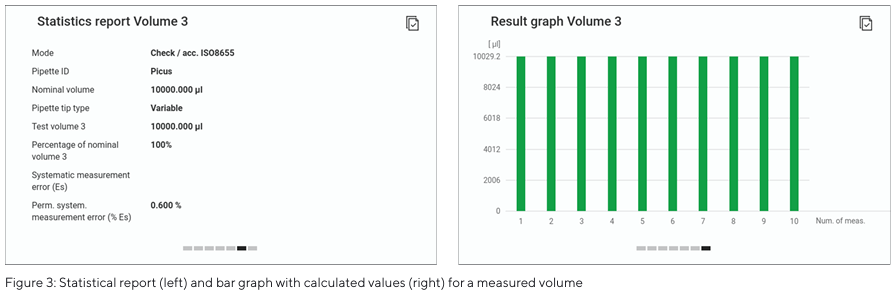

The pipette check software offers a database for pipettes and templates for various Sartorius pipettes. Basically, pipettes are defined by ID, manufacturer, serial number and nominal volume but additional settings as the check interval, pipette type and pipette shape must be selected. DIN EN ISO 8655 part 2 distinguishes between positive (direct) displacement (type D) and air-displacement (type A) pipettes and for type A pipettes between devices with fixed and variable volume. The nominal pipette volume defines the maximum permissible systematic and random error according to table 1 in DIN EN ISO 8655 part 2 and the test procedure depends upon if the pipette is a device with fixed or variable volume. For pipettes with fixed volume the test procedure consists of 10 repeated pipetting steps at the nominal volume. Pipettes with variable volume must be checked at 10%, 50% and 100% of the nominal volume with 10 repeated pipetting steps per volume

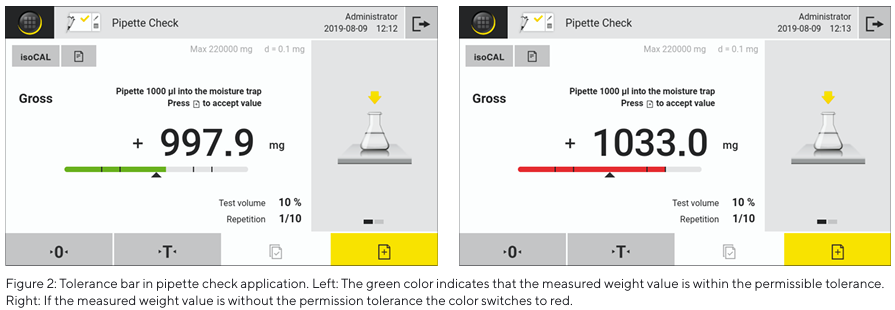

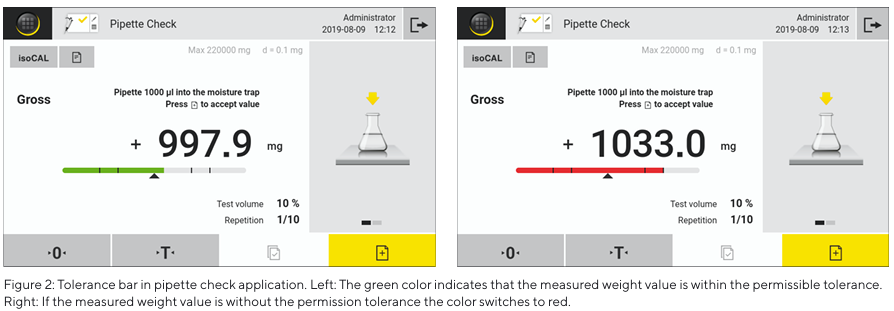

Before the test procedure is started the pipette tip manufacturer, product number and lot number can be entered and recorded. The user is guided through the process and during the pipetting step supported by a tolerance bar displaying the permissible errors. The maximum permissible systematic error (Es) defines the outer limit and the maximum permissible random error (CV) the inner limit of the tolerance bar. If the measured weight value is within both limits the tolerance bar shown in green, if the weight value is between both limits the tolerance bar is shown in yellow and if the weight value is without both limits its shown in red (Fig. 2).