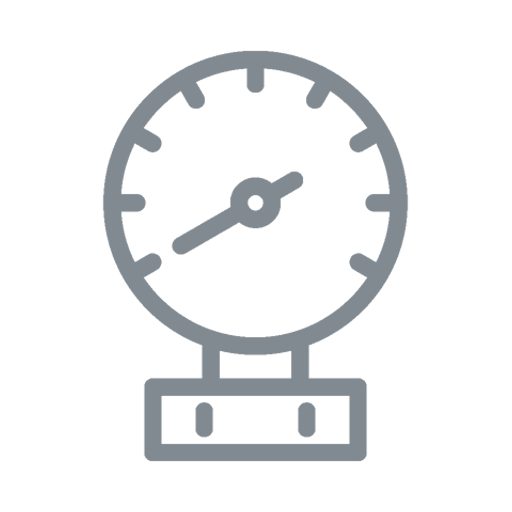

제품소개 Products

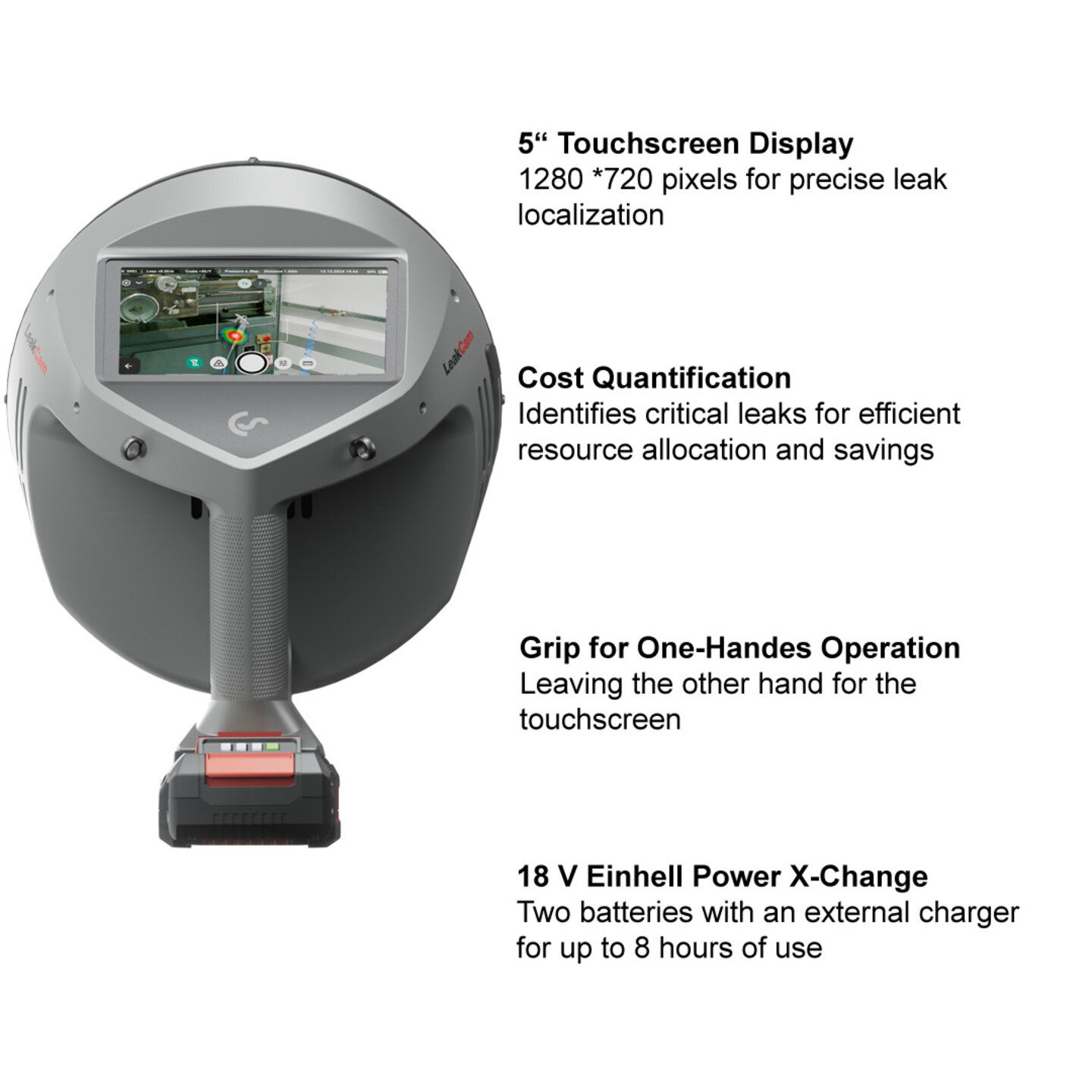

리크디텍터 LeakCam 600 - all relevant leakages at a glance 모델명: LeakCam 600

▶ The power beam forming algorithm - enables simultaneous detection and visualisation of multiple leakages from long distances

▶ 64 ultrasonic microphones arranged at a maximum distance of 20 cm enable the precise localisation of leakages from a distance of up to 20 metres with a compressed air leakage of 10 € / year.

▶ Customisable frequency range from 2 to 80 kHz for accurate leak detection, even in noisy production facilities, sources of interference are effectively masked.

▶ Intuitive operation without the need for training.

▶ 5" HD display and 13 megapixel camera for clear, detailed visualisations.

▶ Ergonomic design with one-handed handle, neck strap and fastening eyelets for extended use.

▶ Replaceable batteries for up to 8 hours of operating time, enabling uninterrupted work.

▶ Estimation of the leakage volume in l/min or cfm and calculation of the annual costs.

▶ Precise focussing and leakage rate determination thanks to integrated laser distance module.

▶ Compatibility with Leak Reporter V2 and Cloud-solution software for advanced analysis and documentation.

제품 카달로그

견적문의

The LeakCam 600 precisely detects compressed air leaks and leaks in compressed gases - even in noisy industrial production environments. Equipped with 64 ultrasonic MEMS microphones and the Power Beam Forming algorithm, it visualises multiple leakages simultaneously and enables them to be located quickly from a great distance. This saves you time when searching for leaks, reduces energy costs and increases the efficiency of maintenance.

Energy efficiency and potential savings with the LeakCam 600

In industrialised countries, around 10% of total industrial electricity consumption is used for compressed air generation, in Germany the figure is as high as 14%. Leakages represent a significant loss of energy. Most compressed air systems have losses in the range of 20% to 40%, in poorly maintained systems even more than 60%. Compressed air leaks often waste 8760 hours of energy per year and extend the operating times of compressors, which also shortens maintenance intervals.

Repairing compressed air leaks therefore sustainably reduces energy consumption, provides a hedge against rising electricity prices and reduces the load on the compressors. In some cases, individual compressors can even be switched off after the leakages have been repaired or production can be expanded with the freed-up capacity.

How does an acoustic/ultrasound camera work for leak detection?

Acoustic and ultrasonic cameras have several microphones whose signals are bundled by the beamforming algorithms used to visualise sound sources in the camera's field of view. The selectable frequency range of the devices depends on the microphones used and their arrangement. The ultrasonic range around 40 kHz is typically used to detect leaks of pressurised gases, as this is where the characteristic sounds of gas leaks are best captured. Acoustic noises are completely filtered out so that leakages can be efficiently detected even in noisy production environments.

3x better leak detection thanks to power beamforming instead of standard beamforming

The LeakCam 600's Power Beamforming algorithm uses the signals from 64 ultrasonic MEMS microphones and their positions to localise multiple leakages simultaneously. With a unique dynamic range of up to 20 dB, the LeakCam enables the simultaneous detection of leaks of different volumes - without larger leaks or ultrasonic noise masking smaller leaks. The dynamic range therefore describes the ability to recognise sound sources of different volumes without loud sources masking quiet sources. In comparison, conventional leak detectors using the standard beamforming algorithm only achieve a dynamic range of 3-4 dB, which severely limits their ability to detect multiple leakages at the same time.

Thanks to this technology, the LeakCam 600 can scan large areas without overlooking small and medium-sized leakages. The maximum distance of 20 cm between the microphones also ensures particularly precise leak detection - even over longer distances - and guarantees accurate and efficient leak detection.

Why does the mere detection of compressed air leaks not necessarily save energy/money?

Detecting compressed air leaks alone does not save energy/money. In order to reduce energy consumption, it is necessary to eliminate these leakages in a second step. The LeakCam 600 helps by storing important information directly at the leak, which is necessary for the repair:

-

Where is the leak located?

-

What needs to be done to fix the problem?

-

What are the estimated costs / energy consumption / CO2 emissions for each leak in total for the whole audit?

-

Up to two pictures of the leak showing the leaking element

How is the leakages data managed after detection?

The data from an audit with potentially hundreds of leaks can be managed locally with the Leak Reporter V2 software or online with the Leak Reporter Cloud Solution. With just a few clicks, automatic leakage reports (PDF, CSV) can be generated containing all relevant information on each leak and a general overview. The resulting report can be used as a work plan for maintenance staff and also serves as documentation for ISO 50.0001 certifications and energy managers.

The LeakCam 600 is therefore a holistic solution for leakages management that enables significant energy and cost savings.

Leak testing and leak detection for other gases and vacuum:

In addition to compressed air leaks, the LeakCam 600 can also detect and visualise leakages of nitrogen, argon, methane and CO2, as long as they have a pressure of around 0.3 bar (relative to the atmosphere) and a loss volume flow of around 0.05 litres per minute. In addition, the LeakCam 600 is also suitable for leakage tests and other gases, provided that the leakages and pressure parameters are given. For leak tests in production processes, an ultrasonic transmitter can also be used if its volume fits into the test specimen.

Ergonomic carrying concept with exchangeable batteries

The carrying system of the LeakCam 600 offers maximum comfort and optimum ease of use. The cross strap included in the set holds your leak detector securely and within easy reach in front of your chest. Thanks to the Einhell 18 V 2 Ah (approx. 2.5 hours) and 18V 4 Ah batteries (approx. 5 hours) included in the set, you benefit from a flexible power supply with minimum weight for extended audits. With the external charger, you can use one battery while the other is charging, allowing you to work without interruption.

-

Relief for neck and shoulders: Ergonomic weight distribution on the upper body.

-

Stable fixation: No swinging - for precise work and easy touchscreen operation.

-

Customisable: Adapts to any body size.

-

Quick handling: Easy to put on and take off thanks to the quick-release fastener.